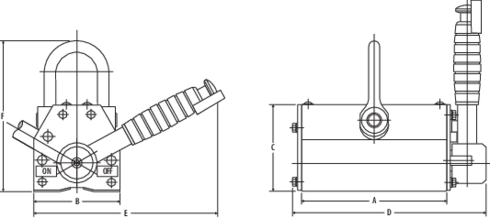

REMA QPM Neodymium permanent lifting magnets are suitable for lifting and transporting flat and cylindrical ferromagnetic materials ("magnetically supported as steel").

Properties

- Safety factor 3.5.

- High-quality Neodymium magnet material [NdFeB].

- Virtually no residual magnetism after decoupling prevents accidents.

- Simple and light lever operation with safety button.

- V-groove makes it possible to hoist cylindrical workpieces next to flat surfaces.

- Compact and robust construction with a large lifting eye.

Type selection:

- Choose the type of magnet to match the load to be lifted.

- Important features are the thickness, weight, size of the magnetic surface, material specification, surface structure, air gap and symmetrical load.

Application:

- REMA QPM permanent lifting magnets can be used as grabs in lifting and hoisting applications for horizontal and vertical materials handling in stores, steel construction manufacturing plants, machine and assembly bays etc.

IMPORTANT:

- Never exceed the safe workload.

- The full lifting force is only achieved if the surface of the steel plate to be lifted (St 37k and 25 mm thick) is processed, smooth and clean.

- Note that only one plate is lifted at a time when lifting thin sheets from a stack.

- Note the “peeling action” when lifting thin plates, these will bend and can become detached from the lifting magnet.

- Never let a lifting magnet come down hard on the ground.

- It is forbidden to be under the load of a lifting magnet, no persons should be put in danger while working with lifting magnets.

- Never lift loads on which loose objects are located.

- Do not lift uneven and porous workpieces.

- Surface must be dry, clean, oil and grease free.

- Lifting magnets only start on company-safe cranes and load hooks etc.

- Prevent shock loads during lifting and place the load in a controlled manner.

- Always check the quality of the control knob on the handle, guide and safety pin before use.

- Have the lifting magnet inspected and inspected by an authorized person or body every year.

- Marking: According to standard, CE-marked

- Standard: EN 13155, EN 12100

- Safety factor: 3,5